Katana Hamon learn more about this fascinating pattern on the katana blade

Everything You Need to Know About Hamon

The Japanese term "Hamon" means blade pattern. It refers to the differential hardening process's visible impact on the blade. As a sword enthusiast, you should know more about this part of Katana. This guide will help you in this regard.

Table of Content

- What Is Hamon "刃文"?

- Katana Hamon Types

- Straight VS Irregular (Suguha VS Midare) Which is better?

- Jihada, Nie and Nioi : Understand the Katana Hamon Deeper

- Real Hamon VS Fake Hamon

- Common Questions About Hamon

What Is Hamon "刃文"?

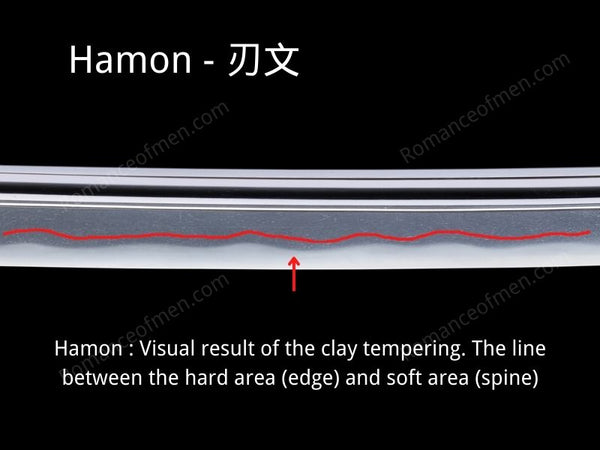

Hamon is the tempering line of a katana blade, between the hard and soft area of the blade. It appears as a white or milky, often wave-like pattern. Hamon in Japanese is "刃文", it literally means "Edge pattern" in English. Hamon is formed during the differential hardening process, also known as clay tempering (Yaki-ire 焼き入れ). Hamon is one of the most important and distinguish feature of a Japanese sword.

To be more accurate, Hamon refers to the tempering line of the blade. And Hamon inside the Katana Tip (Kissaki) is called Boshi (帽子 or 鋩子 in Japanese).

How was the Hamon created?

Hamon is the result of differential hardening. This is a crucial step in traditional Katana making process. In this step, a mixture of clay and charcoal is painted on the blade. The back of the blade (Mune 棟) is covered with a thick coating while the edge receives a thin or no coating. It is then heated till bright red (About 800 degrees). Then it is instantly cooled in water.

The rapid cooling process hardens the katana's edge, while the slower cooling keeps the spine flexible. This is the beauty of the katana design, the edge is razor sharp, seemingly capable of cutting through anything. At the same time, the flexible spine ensures the sword won't easily break during battle.

During the quenching process, the katana blade develops its iconic curve, in Japanese it's called "Sori 反". This happens because different parts of the blade cool at different rates. This variation in cooling speeds causes the blade to curve naturally, giving the katana its distinctive and elegant shape.

The hardened clay is then removed and the blade will be polished. This is the part we can see the Hamon pattern. After quenching, The steel structure of blade edge turn to Martensite, and the back turn to Pearlite, the Hamon is the distinct boundary line where these two structures meet. But it's not visible until the blade is finely polished.

What's the Purpose of Hamon?

Technically speaking Hamon is the byproduct of the differential hardening process. Hamon itself doesn't really serve much functionality purpose. Especially nowadays the modern steel like T10, Spring steel, their cutting performance is better than traditional steel Tamahagane, we don't really need to use differential harden method to improve the blade, Hamon in modern katana are for aesthetic only.

Some might said the Hamon design will effect the blade sharpness, as well as the blade strength. But these are just personal observation, we can't find much solid proof to support it.

Hamon is a huge part to the aesthetic of the katana, especially for Nihonto, showcases the smith's skill in "drawing" the Hamon, reflecting both artistic mastery and technical expertise.

Katana Hamon Types

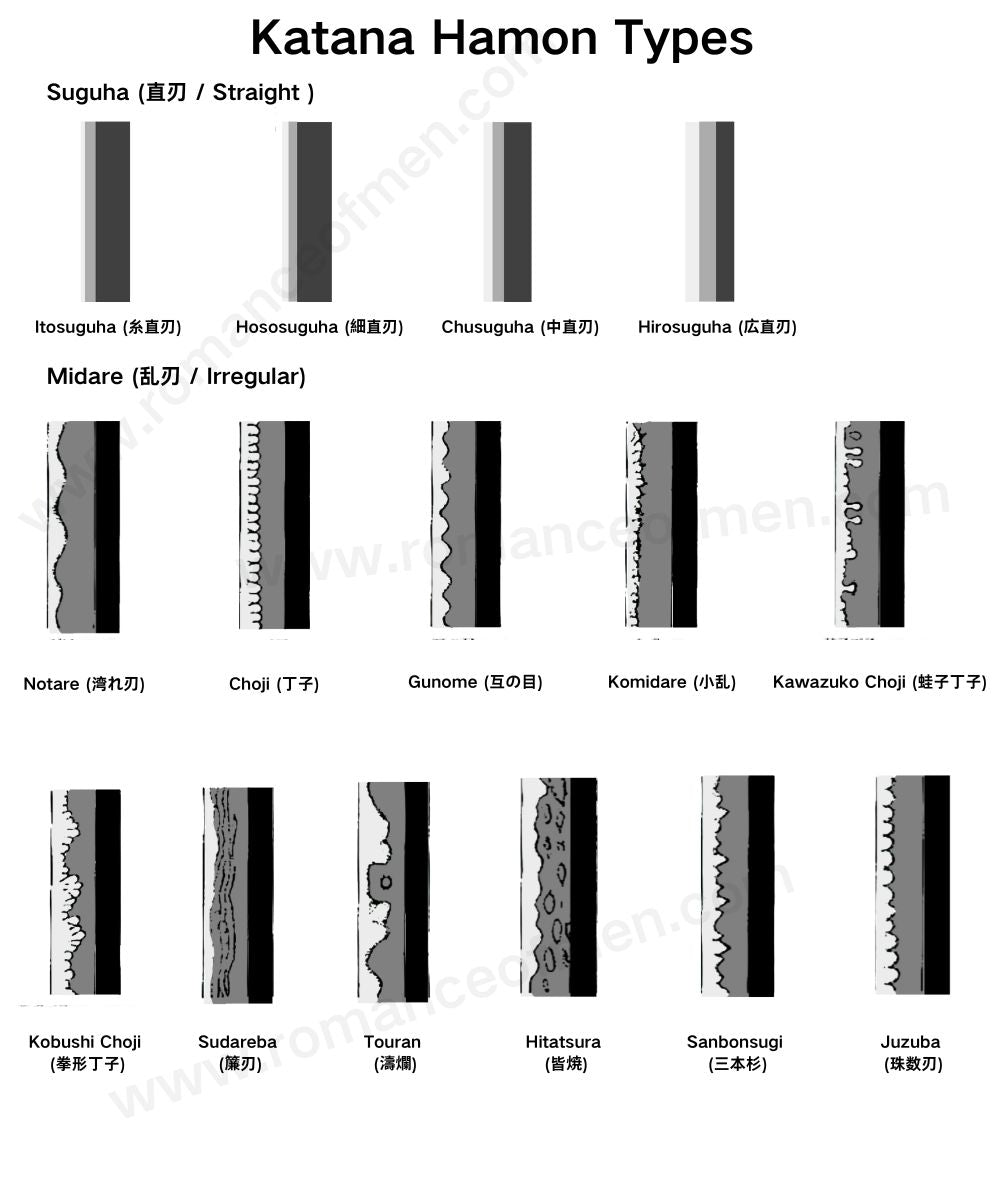

Although there are many different styles of Hamon, the two basic types are straight and wavy lines, all other styles are variation of these two:

Suguha (直刃 / Straight )

Suguha Hamon is a straight line that runs along the blade's edge. Despite its simple appearance, creating a perfectly straight line without any deviation is a challenging task that requires a high level of skill, making it highly valued among sword enthusiasts and collectors.

Suguha has long history and are often seen on Jokotō (上古刀), it's also a popular choice among swordsmiths from the Yamashiro 山城伝 and Yamato 大和伝traditions.

Suguha can be further divided into four main types:

Itosuguha (糸直刃): A very thin, thread-like straight pattern.

Hososuguha (細直刃): A narrow straight pattern.

Chūsuguha (中直刃): A medium-width straight pattern.

Hirosuguha (広直刃): A wide straight pattern.

Midare (乱刃 / Irregular)

Hamon that's not straight is collectively called Midare Hamon. There are over 28 types of irregular Hamon. Here, we will introduce the most popular and common ones. The 3 base types of irregular Hamon are:

Notare (湾れ刃): Wavy hamon, characterized by large, gently undulating waves.

Choji (丁子): Clove-patterned irregular hamon, resembling a series of cloves lined up.

Gunome (互の目): Staggered pattern irregular hamon, featuring a series of round bumps in a continuous sequence.

Other Midare hamon are:

Komidare (小乱): A pattern known as Small Irregular, believed to form randomly from the placement of clay during hardening, originating from the late Heian period.

Kawazuko Choji (蛙子丁子): A variation of the Choji pattern, resembling tadpole shapes, popular from the mid-Kamakura period.

Kobushi Choji (拳形丁子): Resembles a clenched fist, unique to certain regions and noted for its distinct reflections.

Sudareba (簾刃): A unique pattern developed by the Yoshioka lineage in Kyoto Tanba and Osaka Tanba, seen in modern swords.

Touran (濤爛): Evolved from wave patterns to resemble stormy sea crests, pioneered by Sukemitsu in Osaka for modern swords.

Hitatsura (皆焼): Involves heating the entire blade, a technically challenging technique used by Hirotsugu and Akihiro of Sagami.

Sanbonsugi (三本杉): A signature pattern of the Seki (Mino) region, particularly prevalent among followers of Sunnokuni Kanemoto.

Juzuba (珠数刃): A pattern that lies between two styles, believed to have been started by Nagasone Kotetsu in modern swords.

Different types of Hamon often appear mixed or similar to others, it's the bladesmith 's own will to design the Hamon he/she wants, there are no strict rules to follow.

Straight VS Irregular (Suguha VS Midare) Which is better?

Some will say that the pattern of the Hamon affects the performance of a katana. This is not something easy to prove, because real katana made of Tamahagane is too expensive nowadays, no one will really invest that amount of money to test. Because at the end of the day, modern steels like T10, Spring Steel, they are much better choice for cutting than Tamahagane, and proving which Hamon is better seems pointless.

But according to 柴田果 (Shibata Ka), a military swordsmith from the Showa era, and 成瀬関次 (Naruse Sekiji): A military sword repairman who served during the Chinese War of Resistance against Japanese Aggression. There are pros and cons for Straight and Irregular Hamon:

Pros of Straight Hamon (Suguha):

Simplicity and Uniformity: Straight hamons are more straightforward and consistent in pattern, which may contribute to a uniform strength along the blade.

Less Likely to Chipping with Soft Iron: As noted by Naruse Sekiji, straight Hamon is less likely to chip when the steel is softer. This makes them potentially more durable in certain conditions.

Preferred in Soft Steel: For softer steel, a straight Hamon might prevent severe damage like bending, which is critical in less intense combat scenarios.

Cons of Straight Hamon (Suguha):

Vulnerability to Severe Damage: According to the record of Shibata Ka. If the blade hit something very hard, straight Hamon can suffer from larger chippings compared to irregular Hamon.

Less Ideal for Hard Steel: In hard steel, a straight Hamon might not be as effective, leading to potential large chips if the blade's steel is too rigid.

Pros of Irregular Hamon (Midareba):

Better Shock Absorption: The irregular pattern of the Hamon can help stop cracks more efficiently, potentially leading to smaller chips in the blade when strike against hard objects. This makes it suitable for more challenging combat situations.

Historical Preference for Toughness: There has been a historical preference for irregular Hamon in combat swords because they can handle harsh impacts better, making them widely produced not just for their appearance but for their functional superiority.

Adaptability to Hard Steel: With harder steel, an irregular Hamon might be more beneficial, as it can prevent premature breakage, assuming the blade is subjected to rough use.

Cons of Irregular Hamon (Midareba):

More likely To Get Larger Chips in Certain Conditions: According to Naruse Sekiji, wide and flamboyant irregular hamons can be more susceptible to larger chips, suggesting that while they handle small damages well, under severe conditions, they might perform poorly.

Overemphasis on Aesthetics: There's a suggestion that very wide irregular Hamon, especially from later periods, might have focused more on artistic appearance than practicality, making them less ideal for actual combat.

Jihada, Nie and Nioi : Understand the Katana Hamon Deeper

When appreciating a katana, three major aspects are: the Sugata (姿, the shape of the sword), the Hamon (the temper line), and the Jihada (地肌), the pattern of the steel). You might wonder why there are so many patterns on a katana blade. This is because the Japanese sword-making is highly precise and scientific thing, each pattern has its own specific term. When we learn about Hamon, it will be helpful if we learn about the other patterns as well, such as Jihada, Nie (沸) and Nioi (匂).

Jihada 地肌

In Japanese Katana terminology, the material (Steel) of the blade is called Jigane (地鉄) in Japanese, it literally means "Ground Iron", as the foundation of the blade. The pattern of Jigane is called Jihada (地肌), means the skin of the ground, also known as 鍛え肌, means the skin of forging.

In the traditional katana making process, the swordsmith will mixed steel with different carbon content, fold and forge them repeatedly. The parts with higher carbon content appear darker and form the visible patterns after polishing. this is Jihada.

There are over 20 types of Jihada, but the 5 main types of Jihada are Itame-hada (板目肌), Masame-hada (柾目肌), Mokume-hada (杢目肌), Ayasugi-hada (綾杉肌), and Mujihada (無地肌). It's common that various types of Jihada found in the same blade.

In short, the Hamon highlights the swordsmith's skill in quenching the blade, while the Jihada reveals the beauty of the steel forging process.

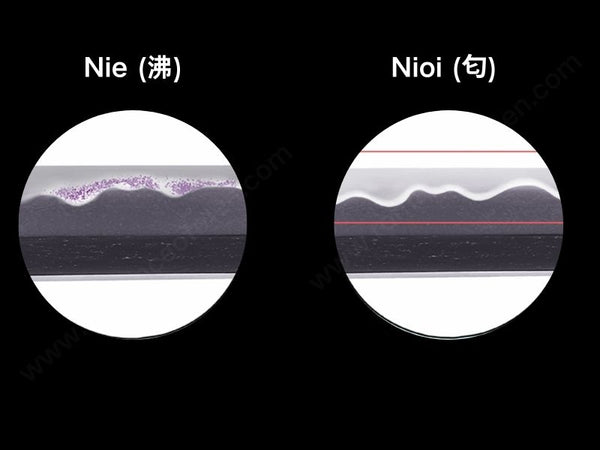

Nie (沸) and Nioi (匂)

In Japanese swords, the terms "Nie" (沸) and "Nioi" (匂) refer to specific types of microscopic particles that form in the blade's pattern (hamon) during the hardening (quenching) process.

Nie (沸) are relatively coarse particles that are visible to the naked eye. They appear as bright, sparkling spots along the Hamon and are a result of the steel crystallizing into a structure called martensite during quenching.

Nioi (匂), on the other hand, consists of finer particles that create a misty or whitish appearance when viewed against light. These finer particles are also martensite but are so small that they are not easily distinguishable with the naked eye.

Both Nie and Nioi are essentially the same type of steel structure, but they differ in their appearance due to variations in quenching temperature and cooling speed during sword-making. The proportion of Nie and Nioi in a sword's Hamon can indicate the specific forging techniques and traditions (den) a swordsmith has mastered. A Katana blade with more Nie is referred to as having a "Nie-deki (沸出来)" finish, whereas one with more Nioi is known as "Nioi-deki (匂出来)."

Moreover, the term "Nioiguchi (匂口)" refers to the boundary between the Hamon and the rest of the blade, and how distinct this boundary appears can further classify the quality of the finish—sharp and clear boundaries are described as "tight Nioiguchi (匂口締まる)," while blurred ones are referred to as "sleepy Nioiguchi (匂口ねむい)."

Real Hamon VS Fake Hamon

Thanks for modern technology, using carbon steel to forge a katana with real Hamon is no longer a super expensive thing. But there are still plenty of sellers selling katana with fake Hamon, here we will introduce the common types of fake Hamon and how you can tell the difference:

Common Types of Fake Hamon:

Wire Brushed: Low-end katanas might have a fake Hamon applied using a grinding wheel to fake the appearance of a real temper line. They will cover the blade with a wavy shape paper, and "grind" out the wavy pattern.

Acid Etching: Similar to the wire brushing, but instead acid is used to etch a line that looks like a Hamon. This method is often used on mid-range swords. For "High-end" cheap katana they will use more detailed acid etching to create a cosmetic Hamon.

How to Tell the Difference betwen Fake and Real Hamon:

If you have seen many katana, telling a real Hamon is not a difficult thing. But if you are new to katana and worry about getting a fake Hamon blade, here are some guidelines to help you:

Texture and Depth: A real Hamon has a 3D quality with granularity and varying color tones, reflecting the complex changes in the steel's crystalline structure. A fake hamon tends to look flat, overly bright, and uniform.

Polishing: Real Hamon are revealed through traditional polishing methods that enhance the steel's different structural characteristics. Even real Hamon will be disappear after the blade is re-polished, or re-quenched. So if your Hamon can be polished out, it doesn't necessary means it's fake. However the polishing quality of a real Hamon blade, is always better than the fake ones.

Hardness Test: Using a Rockwell Hardness File can help determine if a Katana has been differentially hardened, which means if the Hamon is fake or not. If the spine and edge have the same hardness, the Hamon is likely fake.

If you are buying a Katana mainly for decoration and you don't want to spend too much on it, fake Hamon isn't a bad thing. It makes budget swords more visually appealing. Sellers need to be transparent about the nature of the Hamon. Marketing a Katana with a fake Hamon as having a real one is unethical and misleading. Fake Hamon are acceptable on decorative pieces but should not be misrepresented as genuine, which would be dishonest and bad for business. In our custom katana section, we have both fake Hamon and real Hamon blades, and they are clearly labeled so our customer knows what they are paying for.

Common Questions About Hamon

Do All Katanas have Hamon?

Yes and no, depends on your definition of the word "Katana".

If by Katana you mean the Japanese style curved single edge sword, then not all of them should have Hamon. Because for katana using modern steel like spring steel, they are already suprior steel than Tamahagane, they don't really need differential harden to improve the steel. Hence for modern steel katana, the Hamon is there mainly for aesthetic reason.

If by Katana, you mean the authentic Japanese swords (Nihonto), then yes they should all have Hamon, because the definition of Japanese sword, means a sword should be made in Japan, made of Tamahagane, using traditional forging process, only these swords can be called "Katana". The concept of Katana in Japanese means more than swords like Katana (Uchigatana), Tachi, Wakizashi etc, even Polearms like spears (Yari), Naginata, Nagamaki, can be called "katana" as well, and they also have Hamon.

Why does Hamon look white

Many people, especially those not deeply familiar with Japanese swords, might think that the Hamon is just the whitened part of the blade. However, this is a common misconception. The white part is actually the result of a polishing stage known as "Hadori 刃取".

In Hadori polishing stage, the polisher, known as "Togishi" (研師), will carefully use a very small, thin piece of whetstone, that was cut out to fit the shape of Hamon, and polish out the general shape of Hamon, creates a whitened, frosted appearance, make the Hamon more visible.

Conclusion

Hamon is rather tough to construct. Thus, numerous sites sell Katanas featuring artificially crafted phony Hamons. So, it's best to ask for an expert's opinion and go for high-end ones while buying a Katana. Thanks for reading through. Good luck!