Katana Blade What you should know about the soul of this legendary weapon

The Katana Blade: A Comprehensive Guide to the Art and Craft of the Katana

Famous for its sharpness and strength, the katana is one of the finest swords in history, It is also well known for its beauty. The blade of a katana is the most fascinating part, if you are a sword enthusiast, you might want to know more about the Katana blade. This guide will help you in understand more about the katana blade, from material, size, forging to various shapes and steel folding, offering a comprehensive overview of its history, cultural significance, and the meticulous craftsmanship involved in its creation.

Table of Content

- Introducing the blade of Katana

- Katana Blade Measurements

- Katana Blade Material

- Katana Blade Construction / Lamination Methods

- Katana blade shape / Geometry

- Major Parts & Terminologies of Katana Blade

- The Katana making process (Blade)

- Katana blade maintenance

Introducing the blade of Katana

In Japanese, "Katana (刀)" literally means "single-edged sword", to many people's surprise, Katana actually refers to many types of Japanese swords, even included long range weapons like Spears (Yari 槍) or Naginata 薙刀 . For English speakers, most times we actually refer to Uchigatana (打刀) or Tachi (太刀).

It's important to understand that in Japanese, "Katana (刀)" refers to the blade itself only, other fittings are called Koshirae (拵). This distinction is unique compared to the broader definition of "sword" in other contexts, where the entire assembly, including the handle and sheath, is collectively referred to as a "sword".

Today, 'Nihonto' (日本刀) is the most accurate term for a Japanese sword, combining 'Nihon' (Japan) and 'to' (sword) to mean 'Japanese sword'. Historically, Japanese referred to swords as "刀" (Katana, single-edged) or "剣" (Ken, double-edged) without specifying their nationality. The term 'Nihonto' came into use after the late Edo period to differentiate domestically crafted swords from imports. Only swords made in Japan using traditional methods (folding and forging 折り返し鍛錬) and Tamahagane (玉鋼) steel qualify as 'Nihonto', much like the specific designation of 'Champagne' for certain sparkling wines.

Katana Blade Measurements

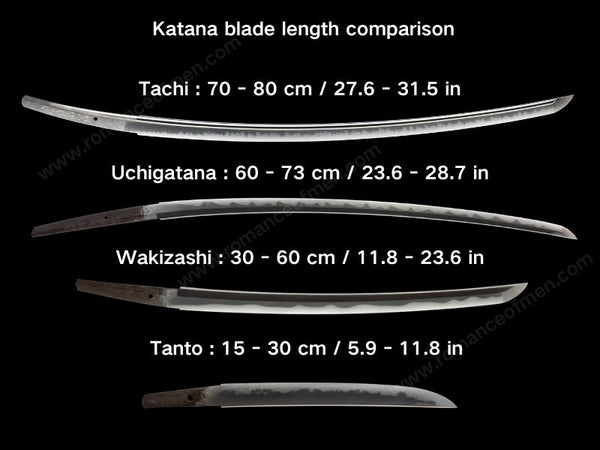

The typical length of a Katana (Uchigatana) blade ranges between 60-70 cm (23-27 inches), a standard influenced by Edo period shogunate regulations, which dictated sword length based on one's social or official rank. Initially, a length of approximately 69.6 cm (27.4 inches) was authorized for martial arts practitioners, a standard set during the reign of the third shogun, Tokugawa Iemitsu. This was later adjusted to 68.2 cm (26.8 inches) under the fourth shogun, Tokugawa Ietsuna.

For individuals practicing iaido, it's recommend to use katana with customized blade length, though preferences can vary across different schools and dojos. A rough formula for estimating a suitable katana blade length involves multiplying one's height in centimeters by 0.43. for example, for a person with a height of 175 cm (approximately 5 feet 9 inches), the estimated Katana blade length using the formula is about 75.25 cm, roughly 29.63 inches.

While this provides a useful starting point, the ideal length and weight of a Katana are usually subjective, determined by an individual's specific physical characteristics and personal preferences, with distinct considerations for males and females.

Katana Blade Material

As mentioned early, only swords using Tamahagane can be considered "Nihonto" Japanese sword. However, due to its cost and craftsmanship, Tamahagane can be quite expensive, nowadays an authentic 'Nihonto' (日本刀) can easily cost you at least $3,000. Fortunately, there are modern alternatives for crafting katana (even they are not Nihonto) that offer both quality and affordability. These include T10 steel, Pattern Steel, and Spring Steel, among others, which we will explore in further detail.

Traditional Steel: Tamahagane (玉鋼)

Image source: Wikipedia

Tamahagane, literally means "Jade / Jewel Steel" in Japanese. Why is it called Tamahagane? There are several theories. One suggests the name means "jewel," highlighting its value. Another theory comes from its high regard in military arsenals as a substitute for superior steels, while a third ties the name to its use in making cannonballs, emphasizing its importance and utility.

Tamahagane was created through the traditional tatara method (たたら製鉄). Usually, impurities in the raw materials, like sand iron and charcoal, would worsen the final product's appearance and properties. However, the tiny impurities in tamahagane actually enhance its toughness and sharpening ability through repeated folding and forging.

Tamahagane is has low impurity and high carbon content (0.3% to 1.5%), making it ideal for creating swords that are tough and sharp. Tamahagane is one of the best types of steel in ancient times, However, when compared to modern steels, Tamahagane falls short in many terms like hardness, sharpness, and edge retention.

Tamahagane continues to be a highly valued material for Japanese swords, not necessarily for its cutting performance but rather for its aesthetic appeal. This traditional steel is prized for the unique beauty it imparts to the blades, including the creation of intricate patterns and the beatifuly hamon line that symbolizes the artistry of Japanese swordmaking.

Tamahagane carries with it a deep cultural and historical resonance, transforming every sword made from it into something far beyond a simple weapon. These are true masterpieces, a testament to centuries of tradition and the incredible dedication of the swordsmiths who work with it. It’s about honoring a legacy that’s been handed down through generations, making every Tamahagane blade a precious slice of history.

Modern Steels:

1045 Carbon Steel: This is a basic form of carbon steel with about 0.45% carbon content. It's a popular choice for katana because it's relatively easy to sharpen and offers a good balance between hardness and flexibility. Perfect for beginners or those looking for a durable, yet affordable sword.

Manganese Steel: Manganese steel includes a good amount of manganese, which makes the steel tougher and more resistant to impact. This means a katana made from manganese steel can take a lot of use and abuse without breaking.

Spring Steel: As the name suggests, this steel is used in springs because it’s very flexible. It can bend a lot without breaking and then return to its original shape. This makes spring steel katanas very durable and resistant to snapping.

T10 Steel: T10 is a type of tool steel that is high in carbon and also contains a bit of tungsten. This combination makes it incredibly hard and able to hold an edge really well. Katanas made from T10 steel are known for their sharpness and durability.

Pattern Steel: Also known as Damascus steel, pattern steel katanas are not just about performance; they are about beauty too. The steel is folded and forged in a way that creates beautiful patterns on the blade, making each katana unique. While they are certainly capable as weapons, many appreciate them for their artistry.

Katana Blade Construction / Lamination Methods

The Japanese katana is renowned for its unique combination of a hard edge and a soft spine. This balance provides the sword with the ability to maintain a sharp edge for cutting while being flexible enough to absorb impacts without breaking. How did Katana gets this special ability? The lamination methods used in forging katanas play a crucial role in achieving these characteristics.

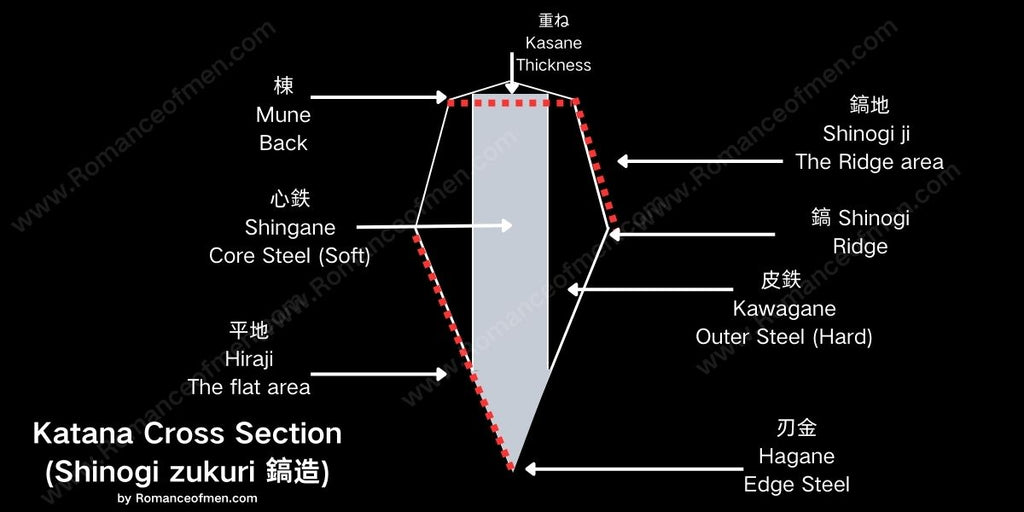

In the crafting of a Japanese katana, different types of steel are used to create a blade that is both sharp and durable, each serving a specific function in the sword's structure. Here's an introduction to the various types of steel used:

Hagane (刃鉄 / 刃金) - "Edge Steel": This is high carbon steel used to form the cutting edge of the katana. The high carbon content allows the edge to be honed to a sharpness that is exceptionally fine, crucial for the katana's renowned cutting ability. However, while it's very hard, it's also more brittle, which is why it's used only for the edge.

Kawagane (皮鉄 / 皮金) - "Skin Steel": This medium carbon steel is used as the outer layer of the blade. It provides a balance between hardness and flexibility, protecting the inner core and providing the sword with the ability to absorb impacts without breaking. It's less brittle than hagane but still hard enough to support a sharp edge.

Munegane (棟鉄 / 棟金) - "Back Steel": This steel has a lower to medium carbon content and is used in the spine or back of the katana. Its lower carbon content gives it greater flexibility and shock absorption properties, balancing the brittleness of the edge steel. This composition helps the katana endure the stresses and impacts experienced during use.

Shingane (心鉄 / 心金) - "Core Steel": Positioned at the core of the blade, shingane is made of lower carbon steel or even pure iron. This material provides the backbone of the sword, offering flexibility and shock absorption. It ensures that the sword can bend without breaking, giving it resilience during combat or cutting exercises.

The major types of katana constructions using the steels above are:

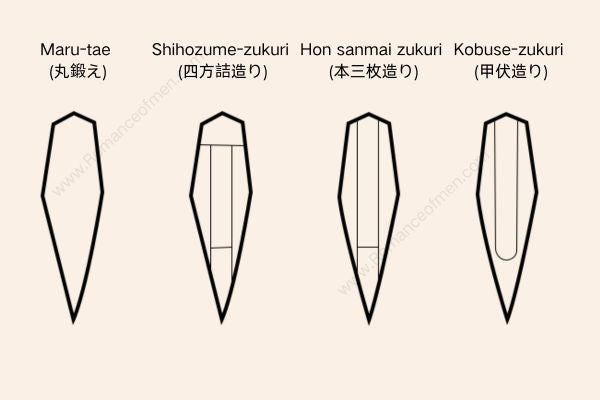

Maru-tae (丸鍛え):

This is a straightforward construction method where the katana is forged from a single type of steel. This simplicity offers a consistent structure throughout the blade, providing good strength and durability. However, it lacks the complex layering found in other methods, which can offer additional benefits like flexibility and edge retention.

Kobuse-zukuri (甲伏造り):

This technique involves crafting the sword with a core of softer, more flexible steel that is enveloped by a harder outer steel layer. The soft inner core allows the sword to absorb impacts and resist breaking, while the hard outer layer maintains a sharp, durable edge. This method effectively balances the blade's toughness and cutting ability.

Shihozume-zukuri (四方詰造り):

An advanced construction technique that involves integrating different types of steel into the blade's spine and edge, creating a complex, multi-layered structure. This method enhances the sword's overall performance, ensuring a hard edge for cutting while maintaining flexibility and strength throughout the blade.

Hon-san-mai-zukuri (本三枚造り):

This construction uses three layers of steel, with a hard outer layer on both sides for a sharp edge and a softer core in the middle to absorb shock. This method is more intricate than kobuse-zukuri, offering an even greater balance between the blade's sharpness, durability, and flexibility.

Katana blade shape / Geometry

Katana geometry (Tsukurikomi 造込み) is the design of a katana's blade, affecting its performance and appearance. Key features include the curve (sori) for slicing, the sharp edge (ha) for cutting, the thick spine (mune) for strength, the ridge line (shinogi) for blade reinforcement, and the pointed tip (kissaki) for thrusting. The blade's width (mihaba) and thickness (kasane) also influence the sword's balance and cutting power. These elements combine to define the katana's functionality and aesthetics. Here are some major types of Katana geometry:

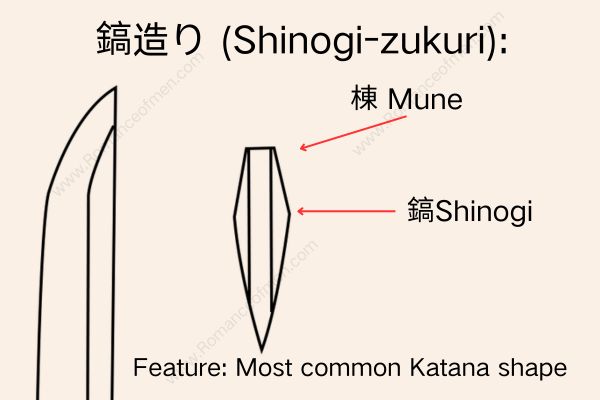

鎬造り (Shinogi-zukuri):

Also known as "Honzukuri 本造り." This style incorporates a ridge (shinogi) that runs along the blade, making it stronger and less likely to break. The shinogi is closer to the spine of the blade, which is a key characteristic of this style.

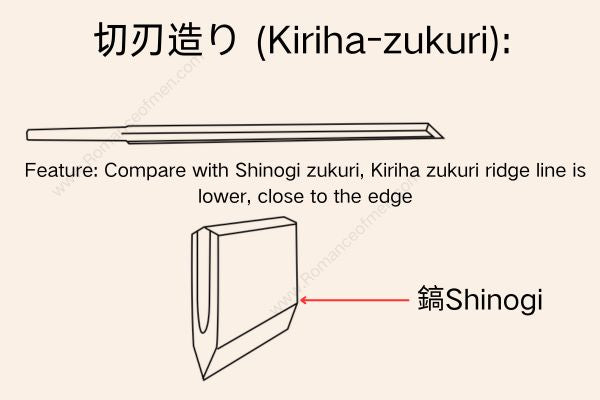

切刃造り (Kiriha-zukuri):

An older style where the ridge line is closer to the cutting edge. In the early Heian period, some swords still had the ridge line near the center, but this evolved into the Shinogi-zukuri where the ridge is closer to the spine.

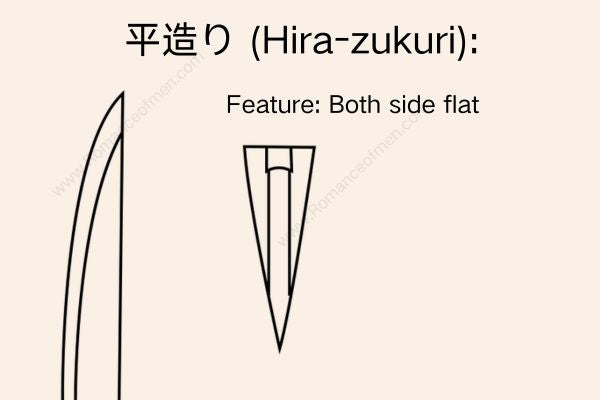

平造り (Hira-zukuri):

This style lacks a ridge line, creating a flat blade surface. Many swords from the Heian period and earlier were made in this style, which later became more common in short swords, known for their sharpness.

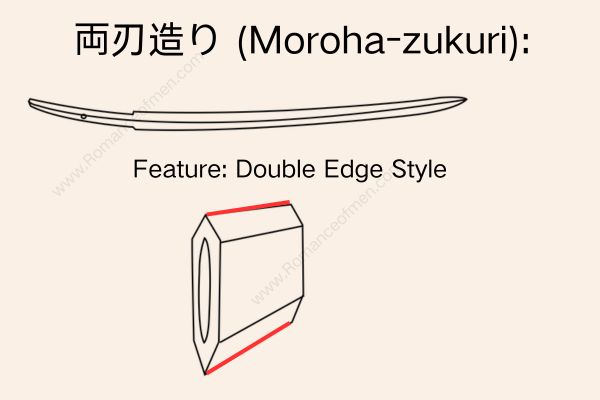

両刃造り (Moroha-zukuri):

A double-edged sword style, common in the Muromachi period, where the blade has cutting edges on both sides, resembling a sword type. There are variants like only the tip part is double edged, called Kissaki Morohazukuri 切先両刃造.

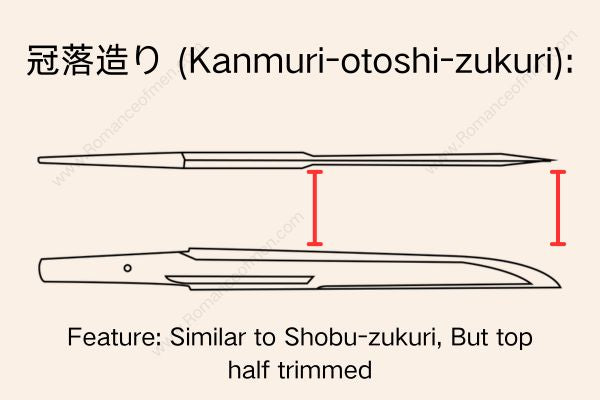

冠落造り (Kanmuri-otoshi-zukuri):

This style features a blade where the top half of the spine is trimmed down, similar to the Ayasugi-zukuri, and is often found in short swords from the old sword period in Yamato.

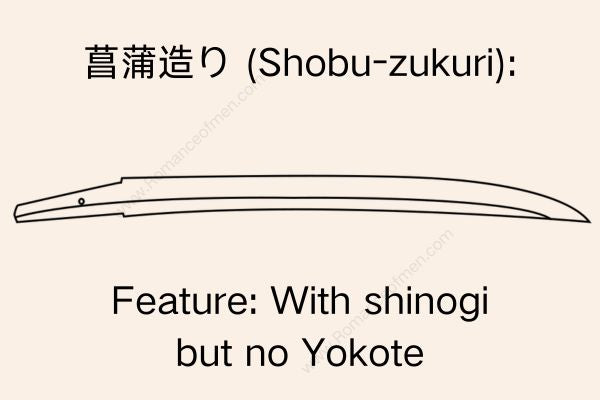

菖蒲造り (Shōbu-zukuri):

Named after the iris leaf, this style has no horizontal ridge line, and the shinogi extends all the way to the tip. It became popular from the middle to late Muromachi period.

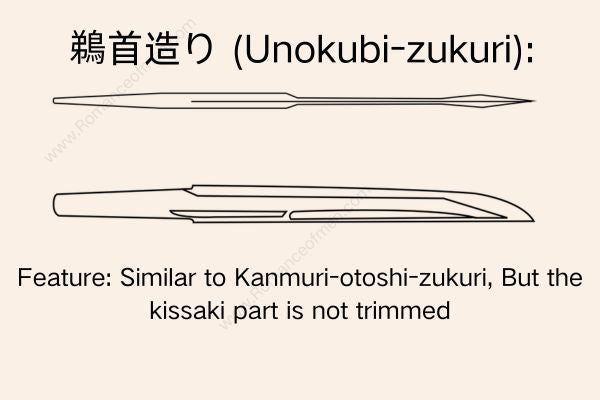

鵜首造り (Unokubi-zukuri):

Resembling a cormorant's neck when viewed from the side, this style has a thinner section between the thicker base and tip of the spine. It's common in short swords and wakizashi from the Kamakura to the Nanbokucho periods.

片切刃造り (Kata-kiriha-zukuri):

One side of the blade is flat (like Hira-zukuri), and the other side has a ridge line (like Shinogi-zukuri). This style is seen in swords from the Nanbokucho period, early Edo period, and the end of the Edo period.

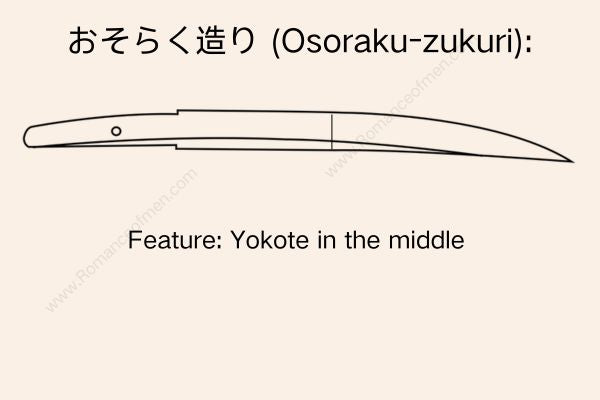

おそらく造り (Osoraku-zukuri):

The side ridge drops significantly towards the center of the blade, creating a larger and sharper tip. This unique style is named after a short sword made by Suruga Sukezane during the Muromachi period, which had "Osoraku" inscribed on it.

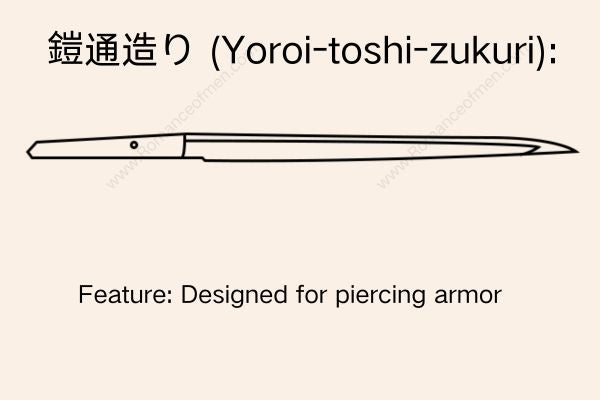

鎧通造り (Yoroi-toshi-zukuri):

Designed for piercing armor, these blades are narrow with thick cross-sections. They were primarily made during the Kamakura and Muromachi periods.

Major Parts & Terminologies of Katana Blade

Japanese swords have many terminologies because they are not just weapons but also cultural artifacts that carry a significant historical and artistic value. Here we will introduce the major parts and terminologies about Katana blades:

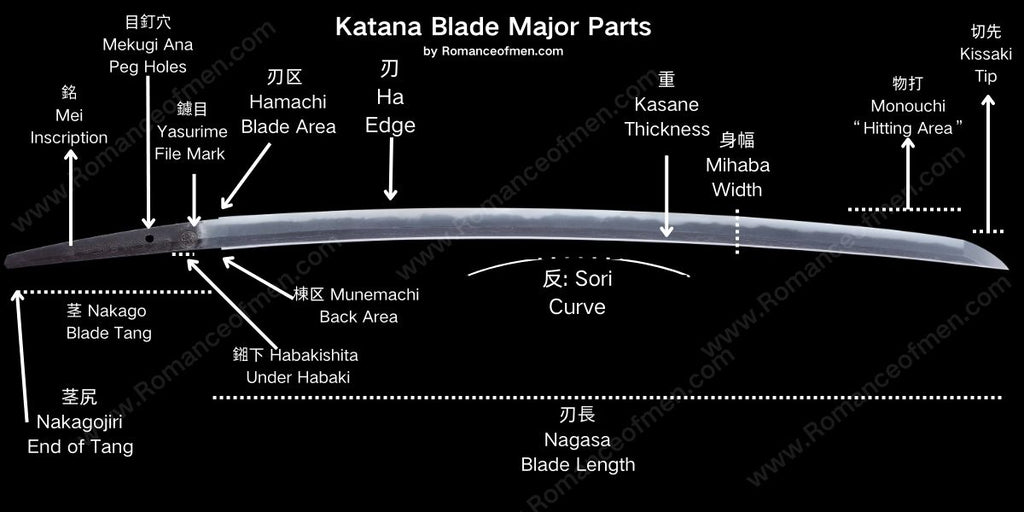

Let's break down these katana blade terminologies into simpler terms:

銘 (Mei): This is the inscription that swordsmith engraved on the nakago (tang) of the sword.

茎尻 (Nakago jiri): The end of the nakago.

茎 (Nakago): Tang, the part of the blade that extends into the handle and is not visible when the sword is assembled.

目釘穴 (Mekugi ana): The hole in the tang for the mekugi (peg) that secures the handle to the blade.

鑢目 (Yasurime): File marks on the tang, increase friction to secure the tsuka. Also can be indicative of the swordsmith's style or school.

鎺下 (Habaki shita): The area near the base of the edge just above the habaki

棟区 (Mune machi): The spine / back section of the blade.

刃区 (Ha machi): The cutting edge section of the blade.

刃 (Ha): The cutting edge of the blade.

反 (Sori): The curvature of the blade.

刃長 (Nagasa): The length of the cutting edge.

重 (Kasane): The weight of the blade.

身幅 (Mihaba): The width of the blade.

物打 (Monouchi): The part of the blade that's meant for striking; usually the last third of the cutting edge closest to the tip.

切先 (Kissaki): The tip of the blade.

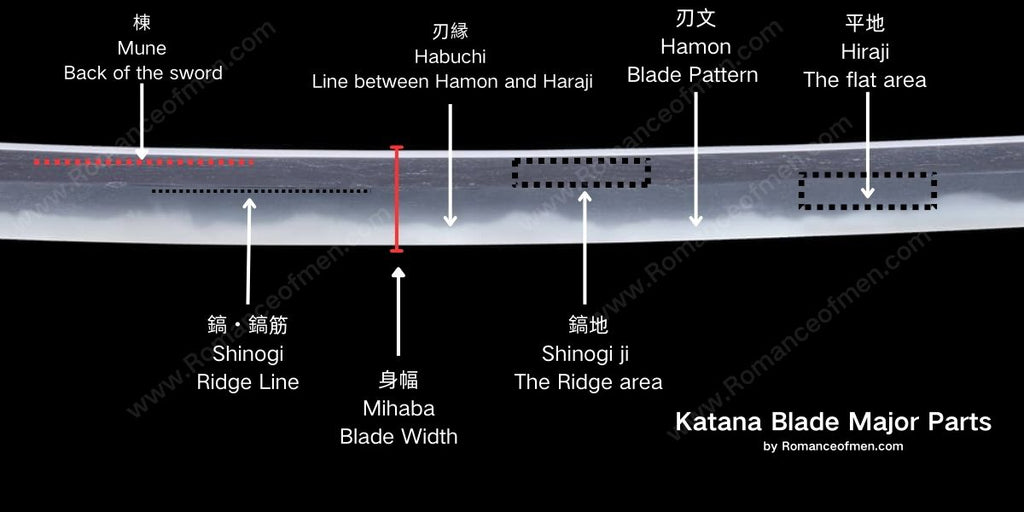

鎬・鎬筋 (Shinogi/Shinogi-ji): The ridge line on the blade's surface that separates the flat part from the part that slopes down to the edge.

刃緣 (Habuchi): The boundary between the Hamon and the Hiraji of a Japanese sword.

鎬地 (Shinogi-ji): The flat area between the ridge line and the spine of the blade.

刃文 (Hamon): The pattern on the blade, this is result of the clay tempered process.

平地 (Hiraji): The flat surface of the blade.

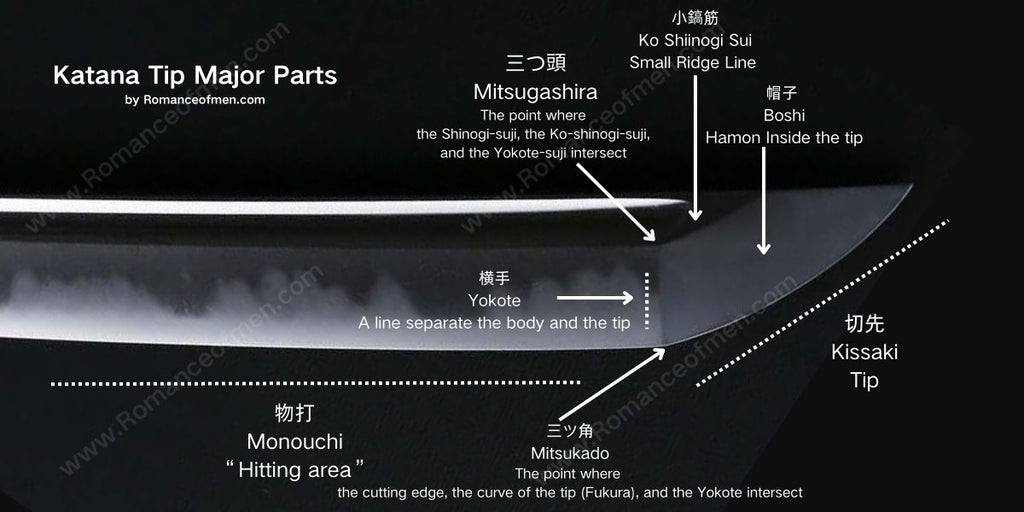

三つ頭 (Mitsugashira): The point where Shinogi suji, Ko Shinogi suji and the Yokote suji intersect.

帽子 (Boshi): The hamon inside the kissaki.

横手 (Yokote): The line that separates the blade's body and the kissaki (tip).

三ツ角 (Mitsukado): The point where the cutting edge, the curve o the tip and yokote intersect.

小鎬筋 (Ko-shinogi-ji): A small ridge line in the kissaki.

The Katana making process (Blade)

Image source: kids.gakken.co.jp

The making of a katana is a complex dance of fire, steel, and spirit, involving series of steps that transform raw materials into a masterpiece of metalwork. We'll give you a clearer view of this craft by walking you through every part of the process. Join us as we explain how these beautiful swords are made, from start to finish, and show you what makes them so special.

Raw Material Preparation: High quality Iron sands were collected as the raw material for the sword. They were smelted in a traditional furnace called a tatara (鞴) to create a special type of steel known as tamahagane (玉鋼).

Steel Selection: The raw Tamahagane is then broken into smaller pieces, sorted by their carbon content, this process is called "小割" Kowari. High carbon steel is hard and will be used as Hagane (刃鉄, low carbon steel is soft and will be used as Shingane (心鉄). These different types of Tamahagane will be forged together in later steps.

Forging: The sorted steel pieces are piled up, heated to a high temperature (around 1300°C) and then hammered to weld the pieces together, this process is called "積み沸し Tsumiwakashi". They were folded and hammered repeatedly to remove impurities and even out the carbon content. This is the famous 折り返し (Origaeshi), folding process. The resulting block of refined steel is tamahagane ready to be forged into a blade.

Shaping: The resulting block of refined tamahagane ready to be forged into a blade. The swordsmith will wrapped the Shingane with Hagane, create a sword with hard edge, and soft spine. They will form the shape of a sword using this block. This process is called "素延" Sunobe

Quenching: The blade is coated with clay in a specific pattern that will later create the hamon, this process is called "土置" Tsuchioki, then tempered to achieve the desired balance of hardness and flexibility. This process is called "焼き入れ"Yakiire

Polishing: Now the blade is almost ready, A "Togishi" (研師) will polish the blade, brings out the beauty of hamon and hada, as well as sharpen the edge.

Modern VS Traditional Katana Making

The modern Katana blade-making process can be very different from the traditional way. Nowadays, one can easily order their own katana, customizing it to their preferences and needs at a very reasonable price. But the traditional katana making process is very time consuming and labour intense, making such a sword very expensive.

However, because there are fewer people willing to dedicate their time in traditional swordsmith industry, some traditional steps are now using modern machines to complete as well. For example during "Forging" (鍛錬) process, there should be a person called ""sente" (先手), who swings a large hammer to hit the steel, many were replaced by mechanical hammers now.

Katana blade maintenance

Maintaining a katana blade is crucial to preserve its beauty, functionality, and longevity. Regular cleaning is essential to prevent rust and corrosion. After each use, the blade should be wiped down with a soft, clean cloth to remove any oils or fingerprints, as these can lead to rust over time. It's also important to apply a light coat of oil, it's recommended to use Choji oil (丁子油), but if you don't have it, it's totally fine to use other mineral oil. The oil forms a protective barrier against moisture.

Storing the katana in a dry place, ideally in its scabbard, or even better, in it's shirasaya 白鞘 , helps protect it from environmental factors. once in a while, the blade may require a more thorough cleaning and inspection to ensure there are no signs of damage or wear. By following these steps, you can help ensure your katana remains in good condition for years to come.